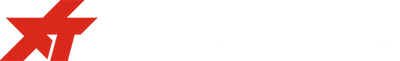

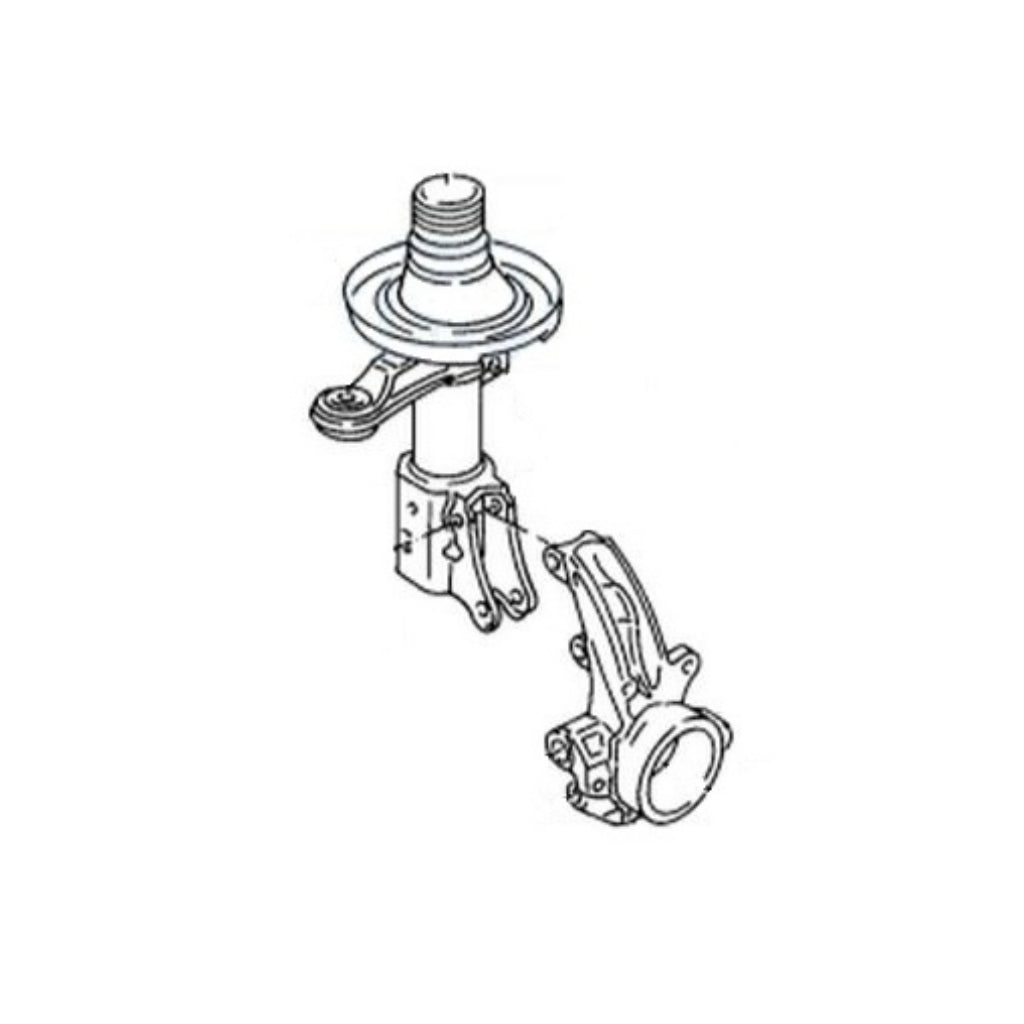

VERKLINE WAS-001 Replica Wishbone Front Axis Kit for AUDI RS2 / S2 (B4)

This item is considered special order and is not available for immediate pickup or dispatch. Price and ETA may vary. Please note that no returns, cancellations, or refunds allowed on special orders.

VERKLINE WAS-001 Replica Wishbone Front Axis Kit for AUDI RS2 / S2 (B4)

ATOMIC-SHOP UAE

26th Street - Al Quoz Industrial Area 2

Dubai DU

United Arab Emirates

ATOMIC-SHOP UAE (RABDAN Motorsport)

14 10b St - Al Quoz Industrial Area 3

Dubai DU

United Arab Emirates

Choose options

This item is considered special order and is not available for immediate pickup or dispatch. Price and ETA may vary. Please note that no returns, cancellations, or refunds allowed on special orders.

This item is considered special order and is not available for immediate pickup or dispatch. Price and ETA may vary. Please note that no returns, cancellations, or refunds allowed on special orders.

What’s Included

- Two wishbones for front axle.

- Two aluminum ball joint carriers milled on CNC machine and anodized in black.

- Two regreasable sport Fluro bearings (22 mm hole).

- Two steel pins to connect with OEM struts (front – please state 17mm, 18mm or 19 mm pin).

- Four steel galvanized locking plates for securing aluminum ball joint carriers.

- All necessary screws for mounting ball joint carriers and steel pins.

Features

- Can be used in conjunction with the standard front sub-frame.

- Made to work with OEM uprights.

- Allows for massive camber adjustment (up to 25mm more versus OEM) and wider track.

- Gives additional caster.

- Works fine with Audi Sport blade type anti roll bars.

- Works with Audi Sport uprights (22 mm bolt).

- Prepared to work with additional trailing arm (front).

- Possible to use with “turn stop” on Audi Sport uprights.

- On the contact area between aluminum ball joint carrier and inside of the wishbone the area is knurled for better grip of the carrier.

- To be used with 37mm diameter bushes for mounting the wishbone to the subframe.

Bending machine used and milling machine for pipe treatment. Pipes are milled, metal plate is stamped, ends of the pipe are pressed and flattened for fastening of bushes, plug and bends are cut out on the laser, bushes are turned and grinded, rocker arm is welded in welding tool, dimensional tolerances: 0,03 mm, concentricity tolerance 0,01 mm, tolerances are checked on separate measurement device.

Knurling is made on the press by inserting the mass of material – 80 metric tons. MIG welding is used to connect all the pipes together to replicate Audi Sport manufacturing process. The wishbone is made of reinforced steel and powder painted in black color.

Notice: Front wishbones increase significantly caster angle.